Electrofusion Welding

ELECTROFUSION WELDING

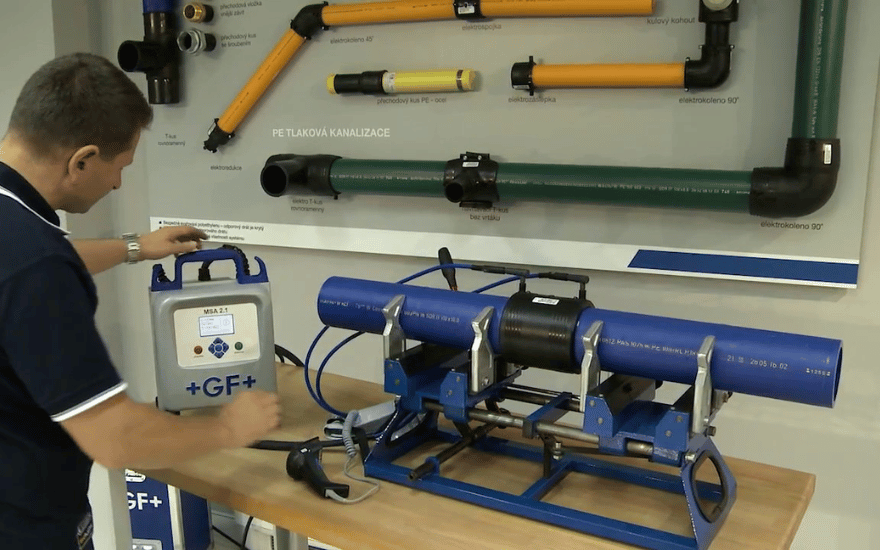

Electrofusion is a simple method of joining PE pipes in circumstances where butt fusion is not practicable, such as where valves, elbows, and tees must be added. Prefabricated fittings are used, incorporating an electrical heating coil which melts the plastic of both the fitting and the pipe, causing them to fuse together. The characteristics of the fitting to be welded, such as the fusion time, are registered via a barcode on the fitting. An electrofusion control unit (ECU) supplies the electrical energy necessary to heat the coil. When the coil is energized, the material adjacent to it melts and forms an expanding pool which comes into contact with the surface of the pipe. The continued introduction of heat energy causes the pipe surface to melt and a mixing of pipe melt and fitting melt takes place; this is vital to produce a good weld.

Benefits of using Electrofusion Welding

- Seamless addition of valves, elbows, and tees to PE pipes.

- Ideal for tight spaces where traditional methods are impractical.

- Produces durable, uniform fusion for long-term pipeline integrity.

- Barcode technology ensures accurate fusion parameters for optimal weld strength.

Cost

of Work

Electrofusion welding is typically used for joining polyethylene (PE) pipes, which are common in gas, water, and industrial pipelines.

The process involves cleaning the pipe surfaces, positioning the electrofusion fitting, and then applying electric current to heat and fuse the materials together, creating a strong joint.

Common applications include gas and water distribution systems, industrial pipelines, and repair of existing pipelines.